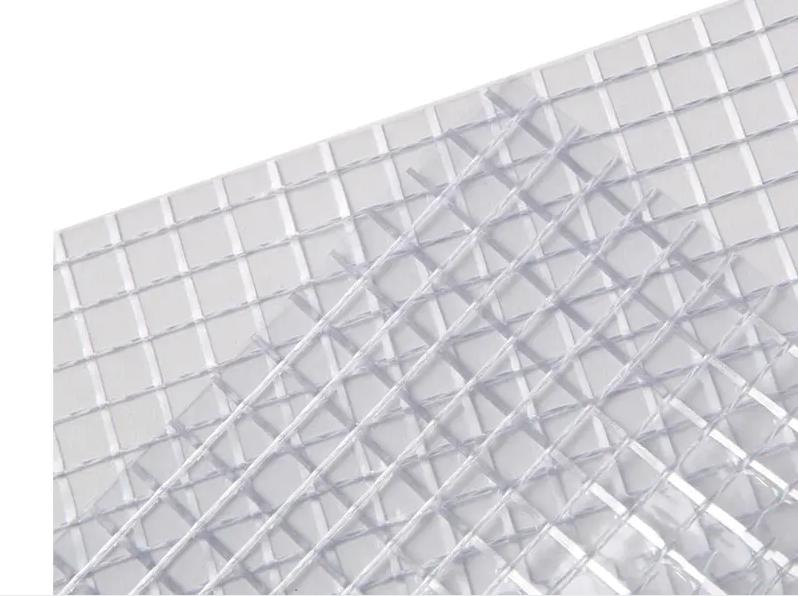

400GSM 1000D 3X3 Transparent PVC Coated Polyester Fabric (PVC coated polyester fabric for short) has become a highly anticipated product in the market due to its physical properties and wide range of applications.

1. Material properties

400GSM 1000D3X3 Transparent PVC Coated Polyester Fabric is made of 100% polyester fiber as the base material, with a layer of transparent PVC (polyvinyl chloride) material coated on the surface. This material has multiple properties:

High strength and durability: Compared with traditional PVC film, PVC coated polyester fabric has stronger physical strength, thanks to the reinforcement of its polyester fiber. This allows the material to resist tearing and abrasion in long-term use and maintain structural integrity.

Transparency: The PVC coating maintains good transparency, allowing light to pass through the fabric while blocking the damage of ultraviolet rays. This property makes it particularly suitable for occasions where lighting and UV protection are required.

Fireproof and chemical stability: PVC material itself has fireproof performance (flame retardant value exceeds 40) and can resist corrosion from a variety of chemicals, such as concentrated hydrochloric acid, 90% sulfuric acid, 60% nitric acid and 20% sodium hydroxide. In addition, by adding specific chemical additives, PVC coated polyester fabric can also have advanced properties such as anti-mildew, anti-frost and antibacterial.

Electrical insulation: The material also has good electrical insulation performance and is suitable for occasions requiring electrical isolation.

2. Production process

The production process of PVC coated polyester fabric is relatively complicated and mainly includes the following steps:

Substrate preparation: Select high-quality 100% polyester fiber as the substrate and pre-treat it to improve the adhesion of the coating.

Coating: The liquid PVC material is evenly coated on the polyester fiber substrate to ensure uniform coating and consistent thickness.

Drying and cooling: The coated fabric enters the oven for drying to solidify the PVC coating and tightly bond with the substrate. It is then cooled to ensure the dimensional stability of the product.

Molding and inspection: After drying and cooling, the fabric is molded and subjected to strict quality inspection to ensure that the product meets relevant standards and customer needs.

3. Application fields

400GSM 1000D3X3 Transparent PVC Coated Polyester Fabric is widely used in many fields due to its excellent performance:

Outdoor tents and awnings: Its transparency and high strength make it an ideal material for outdoor tents and awnings, which not only ensures good lighting effects, but also has excellent wind, rain and UV protection functions.

Building membrane structure: In the field of construction, this material is used to make tensile membrane structures, awnings, etc., providing beautiful and practical sunshade and rain protection solutions for buildings.

Transportation facilities: In the field of transportation, PVC coated polyester fabric can be used to make highway sound barriers, tunnel side walls, etc., effectively improving the noise and light problems in the traffic environment.

Agriculture and fisheries: Due to its waterproof, wear-resistant and durable characteristics, this material is also widely used in agricultural greenhouse coverings, fish pond protection and other occasions.

Post time: Jul-26-2024